Reliability Services

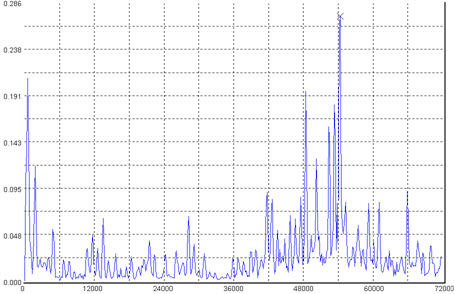

Vibration Analysis

Our

Vibration Analysis Programs can improve your facility's reliability:

Our

Vibration Analysis Programs can improve your facility's reliability:

*

Detect hidden equipment problems

* Regularly scheduled Vibration

Analysis Programs help minimize unscheduled outages & downtime

*

Maximize the life span of existing equipment

* Aid in planning &

scheduling maintenance work

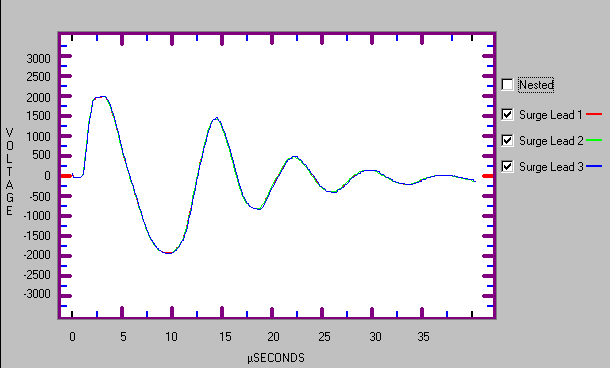

Advanced Winding Analysis

Our

Winding Analysis Programs can improve your facility's reliability:

Our

Winding Analysis Programs can improve your facility's reliability:

*

Motor windings are tested in accordance with IEEE Standards & helps

determine if a motor's insulation system is suitable for continued use

* Testing can detect contaminants & moisture in a motor's insulation

system

* Database keeps track of & stores test results so a motor's

insulation deterioration can be trended over time

* Winding failures

are proactively minimized through periodic testing

Infrared Inspection

Our Infrared Inspections can help find high

resistance/loose connections in your facility as well as other

problems:

*

Predictive maintenance of electrical distribution systems

*

Predictive maintenance of electrical distribution systems

*

Predictive maintenance of heating & cooling equipment

*

Troubleshooting & predictive maintenance of industrial equipment

* Process monitoring

* Product inspection

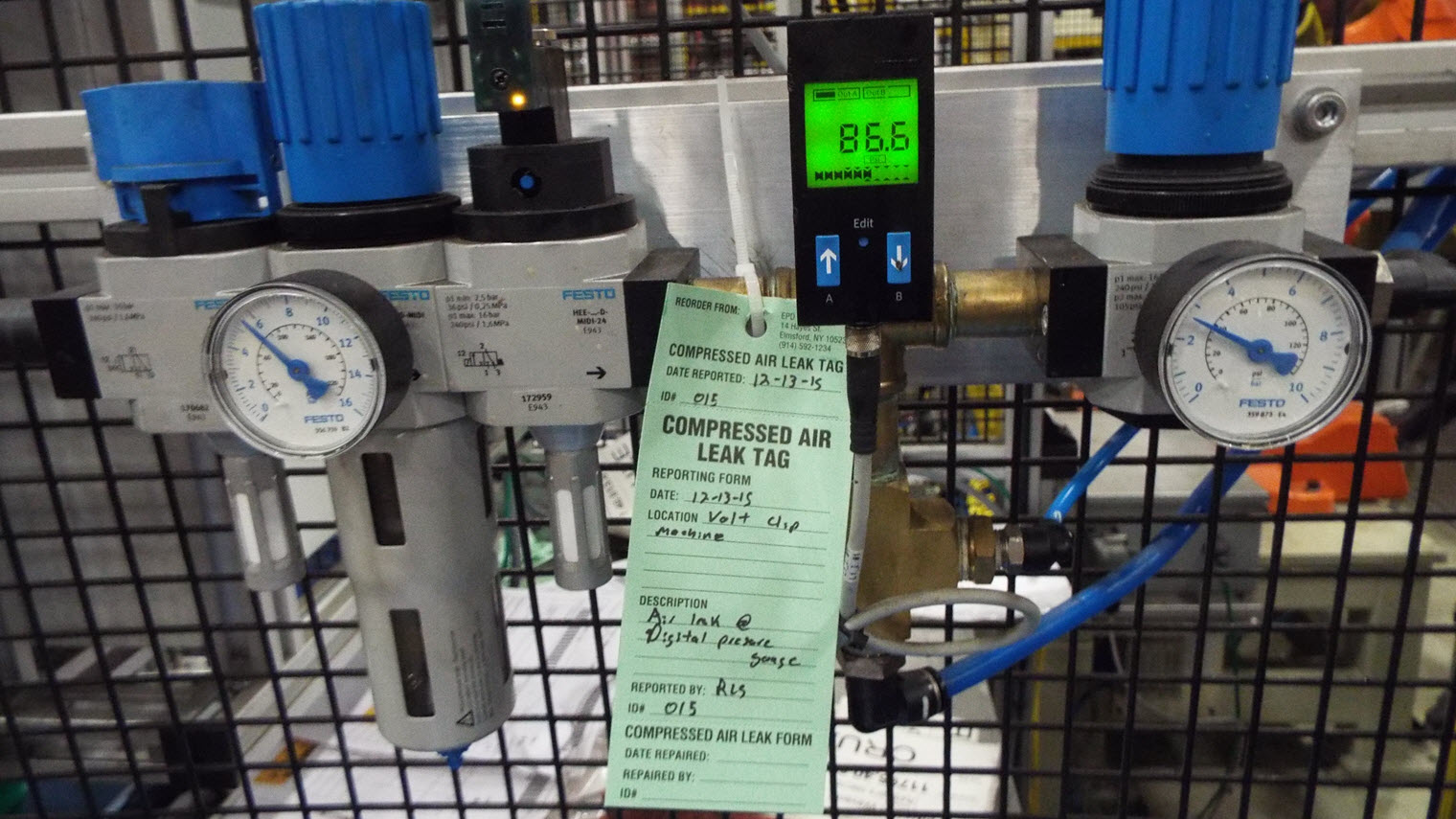

Ultrasonic Inspection

Our

Ultrasonic Inspections can help find costly air leaks in your facility

as well as other problems:

Our

Ultrasonic Inspections can help find costly air leaks in your facility

as well as other problems:

* Pressure / vacuum leak

detection

* Liquid leak detection

* Steam trap inspection

*

Heat exchanger, boiler & condenser leak detection